Plastic

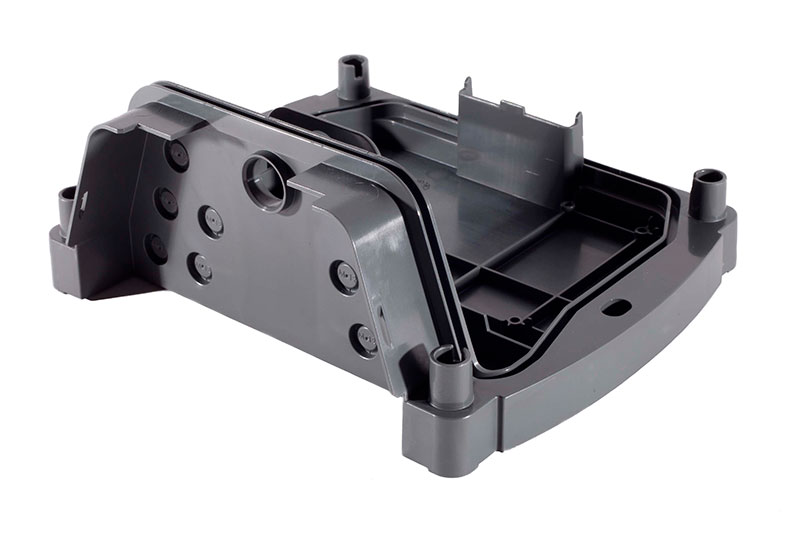

For more than 50 years now, KIK’s core business has been the injection moulding of plastic knowledge, skill and experience are the pillars on which our company is built. In terms of materials, properties and geometry, we are capable of meeting any technically feasible requirement.

Our production unit has 22 up-to-standard computer-controlled injection moulding machines that run 24/7 in a completely controlled environment. The quality of the end-product is assured by state-of-the-art control systems that continuously monitor all critical parameters throughout the process. The machines automatically extract products that might not meet the tolerance requirements in order to subject them to an extra check. With opto-mechanical 3D measurement equipment, for example, we are able to check thickness and other dimension tolerances with micron accuracy.